A particularly detailed and comprehensive guide to plastic recycling machines

Plastic pollution has become one of the most pressing environmental issues of our time, impacting our oceans, wildlife, and even our health. Every year, millions of tons of plastic waste end up in the environment, taking hundreds of years to decompose. However, technology offers a promising solution through plastic recycling machines, which play a crucial role in tackling this crisis by transforming waste into reusable materials.

Introduction to Plastic Recycling Machine

Plastic recycling machines are innovations designed to reduce plastic waste by converting discarded plastics into useful products. These machines are essential in the recycling process, helping to alleviate the burden on landfills and reduce the need for new raw materials. By processing used plastic, we can lessen environmental pollution and promote a circular economy where materials are reused rather than disposed of.

Types and Functions of Plastic Recycling Machines

There are several types of plastic recycling machines, each serving a specific function in the recycling process. Understanding these machines helps us appreciate how they contribute to environmental sustainability.

1. Shredders

Shredders are powerful machines used to break down large pieces of plastic into smaller fragments. This process is crucial because smaller pieces of plastic are easier to handle and process in the subsequent stages of recycling. Shredders use a series of blades to cut the plastic into chips or flakes, which are then ready for further cleaning and processing.

2. Washing Lines

After shredding, the plastic fragments often contain impurities such as food residue or dirt. Washing lines come into play here, cleaning the shredded plastic thoroughly. These machines use water and detergents to remove contaminants, ensuring that the plastic is pure before it moves to the next stage of recycling. Clean plastic is crucial for the quality of the final recycled product.

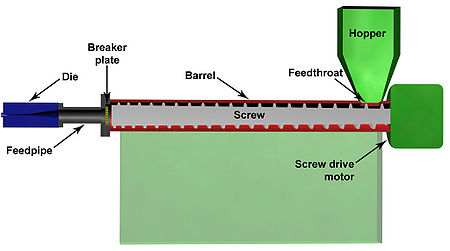

3. Extruders

Extruders are key components in the recycling process. They melt the clean, shredded plastic and then extrude it through a die to form new plastic pellets. These pellets can be used to manufacture new plastic products, completing the recycling loop. Extruders operate at high temperatures, which helps to sterilize the plastic, ensuring that the final products are safe for use.

Operational Processes

The operational process of these machines is interconnected, forming a complete recycling line. Here’s how it typically works:

- Collection and Sorting: The first step in the recycling process is collecting and sorting the waste plastic. Plastics are sorted based on their type and color to ensure compatibility during recycling.

- Shredding: Sorted plastics are fed into shredders where they are broken down into smaller pieces that are easier to process.

- Washing: The shredded plastics then pass through washing lines where they are cleaned to remove impurities, preparing them for melting.

- Extruding: Clean and dried plastic flakes are fed into extruders where they are melted down and formed into pellets, which are then ready to be reused in making new plastic products.

By understanding the types and functions of plastic recycling machines, we can better appreciate the technology’s impact on reducing plastic waste. These machines are not just mechanical tools; they are essential instruments in our ongoing battle against plastic pollution, helping to preserve our environment for future generations. As technology advances, the efficiency and effectiveness of these recycling processes will continue to improve, further enhancing our ability to manage plastic waste sustainably.

Steps and Technological Processes in Plastic Recycling

The process of recycling plastics is intricate and requires a series of steps, each crucial for transforming waste into reusable materials. These steps include collection, sorting, cleaning, shredding, melting, and pelletizing. Below, we’ll explore how various machines are integral to these processes and examine the technological complexities and challenges encountered at each stage.

Collection

The journey of recycling begins with the collection of plastic waste. This includes gathering plastics from households, businesses, and public spaces. Effective collection systems are vital, as they determine the quantity and quality of plastic entering the recycling stream. The challenge here lies in educating the public on proper disposal methods and developing efficient collection logistics to ensure that plastics are collected without contamination.

Sorting

Once collected, the plastics must be sorted. This step is critical because different types of plastics—such as PET, HDPE, and PVC—melt at different temperatures and have distinct recycling requirements. Advanced sorting machines, equipped with infrared technology and other scanning systems, automatically identify and separate plastics based on their resin content and color. The challenge in sorting is dealing with mixed plastics and non-plastic materials that can disrupt the recycling process if not properly segregated.

Cleaning

After sorting, the next step is cleaning the plastics to remove impurities such as food residue, labels, and adhesives. This process typically involves granulators and wash lines that use water and detergents to clean the shredded plastic. The key challenge here is ensuring that all contaminants are removed, as any residue can degrade the quality of the recycled material.

Shredding

Shredding reduces the size of plastic waste into smaller, manageable pieces. Shredders use sharp blades to cut the plastic into flakes or granules. This step is essential because smaller pieces have a larger surface area, making subsequent processes like washing and melting more effective. The technological challenge in shredding involves dealing with plastic items that contain metal parts or other materials that can damage the shredder blades.

Melting

Melting involves heating the clean, shredded plastics to transform them into a homogenous liquid state. This process is conducted in extruders, which apply heat and pressure to melt the plastic. The melted plastic must be carefully controlled in terms of temperature and timing to ensure uniformity and prevent degradation of the polymer chains. The main challenge in melting is adjusting the process parameters to accommodate different types of plastics.

Pelletizing

The final step in the recycling process is pelletizing, where melted plastic is extruded through a die and cut into small pellets. These pellets are then cooled and packaged for sale to manufacturers who use them to produce new plastic products. Pelletizing machines must be precise in cutting and cooling to produce high-quality pellets that meet industry standards. A challenge here is ensuring the pellets are uniform in size and free from any impurities.

Installation and Maintenance of Plastic Recycling Machines

Installing and maintaining plastic recycling machines are critical aspects of running a successful recycling operation. Below are practical insights into the setup, maintenance, and troubleshooting of these machines.

Installation

The installation of plastic recycling machines involves several steps:

- Site Preparation: The facility must be prepared to handle heavy equipment, including ensuring adequate space, power supply, and water access.

- Assembly and Setup: Machines are typically shipped in parts and require professional assembly. Technicians must follow the manufacturer’s guidelines to assemble and calibrate the machines correctly.

- Testing: Before full-scale operation, machines should be tested with a small batch of plastic to ensure they are functioning as expected.

Maintenance

Routine maintenance is vital for the longevity and efficiency of recycling machines. Maintenance tasks include:

- Regular Cleaning: Machines should be cleaned regularly to prevent buildup of plastic residue and contaminants.

- Lubrication: Moving parts require lubrication to operate smoothly and prevent wear.

- Part Inspections: Frequent inspections are necessary to check for wear and tear on blades, belts, and other components.

- Software Updates: For machines with automated systems, keeping software updated is crucial for optimal performance.

Troubleshooting and Care

Effective troubleshooting requires operators to understand common issues that might arise, such as jams, temperature inconsistencies, or mechanical failures. Having a detailed operation manual and training for staff on troubleshooting procedures can dramatically reduce downtime. Moreover, establishing a routine maintenance schedule and keeping a stock of essential spare parts on-site ensures that the recycling process runs smoothly with minimal interruptions.

By thoroughly understanding each step of the recycling process and maintaining the machinery involved, facilities can maximize their output of high-quality recycled plastic, contributing significantly to environmental sustainability.

Economic and Environmental Benefits of Plastic Recycling Machines

The adoption of plastic recycling machines not only promotes environmental sustainability but also offers significant economic benefits. These benefits include cost savings from reduced raw material and disposal costs, potential revenue from recycled products, and long-term profitability through sustainable practices.

Economic Benefits

- Reduced Raw Material Costs: By recycling plastic waste, manufacturers can significantly reduce their dependency on virgin materials, which are often more expensive than recycled materials. This reduction in material costs is one of the primary drivers for companies to invest in recycling technology.

- Increased Efficiency: Modern plastic recycling machines are designed to be highly efficient, reducing energy consumption and operating costs. The increased efficiency translates into lower production costs, making businesses more competitive in the market.

- Revenue from Recycled Products: Recycled plastics can be sold to manufacturers who use them in various applications, from packaging to automotive parts. This not only creates a new revenue stream but also helps in building a circular economy.

- Compliance with Regulations: Many regions are imposing strict regulations on waste management and recycling. Investing in recycling machinery helps companies comply with these regulations and avoid fines or penalties.

- Enhanced Brand Image: Companies that actively engage in recycling initiatives often see an improvement in their brand image and customer loyalty, as consumers are increasingly favoring environmentally responsible companies.

Environmental Benefits

- Reduction in Waste Emissions: By recycling plastic waste, less of it ends up in landfills or incinerators, leading to a significant reduction in methane emissions from landfills and harmful emissions from burning.

- Conservation of Resources: Recycling reduces the need for extraction of new raw materials, conserving resources and minimizing the environmental footprint associated with mining and extraction.

- Energy Savings: Producing products from recycled plastics often requires less energy compared to producing the same product from virgin materials. This energy saving leads to a reduction in overall carbon emissions.

- Biodiversity Protection: By reducing the need to extract new raw materials, recycling helps in preserving natural habitats and protecting biodiversity.

Global Case Studies

Several global case studies highlight the effective use of plastic recycling machines and the positive outcomes associated with these initiatives.

Case Study 1: PET Recycling Plant, Switzerland

A facility in Switzerland specializes in recycling PET bottles, turning them into high-quality food-grade PET flakes. The plant uses advanced sorting and washing technology to ensure that the recycled PET meets strict hygiene standards required for food packaging. The success of this facility lies in its integration of sophisticated machinery with meticulous quality control processes.

Lessons Learned:

- Importance of technology in meeting quality standards.

- The need for strict process controls to produce high-grade recycled materials.

Case Study 2: HDPE Recycling Operation, USA

In the United States, a large-scale operation focuses on recycling HDPE plastics used in milk jugs and detergent bottles. The facility has perfected its sorting and cleaning processes to handle large volumes efficiently. The recycled HDPE is then sold to manufacturers of plastic lumber and outdoor furniture.

Lessons Learned:

- Scalability of recycling operations to handle large volumes.

- Development of a market for recycled products is crucial for the sustainability of recycling operations.

Case Study 3: Mixed Plastics Recycling, Japan

Japan has developed innovative technologies to recycle mixed plastics that are difficult to process. Through chemical recycling, these plastics are converted back into oil, which can then be used to produce new plastic products. This approach not only manages waste that would otherwise be unrecyclable but also reduces oil consumption.

Lessons Learned:

- Innovation in recycling technology can provide solutions for handling complex waste.

- The potential of chemical recycling in managing mixed and contaminated plastics.

These case studies demonstrate not only the feasibility of using plastic recycling machines effectively but also the broad range of environmental and economic benefits that can be achieved. By learning from these successes, other countries and companies can implement and improve their recycling strategies, contributing to global sustainability efforts.

Future Prospects and Challenges

The future of the plastic recycling industry is poised for growth, driven by technological advancements, increasing regulatory pressures, and shifting consumer behaviors. However, substantial challenges need to be addressed to maximize the potential benefits of plastic recycling technologies.

Future Trends

- Advanced Sorting Technologies: Innovations in sorting technology, such as AI and machine learning, are expected to improve the efficiency and accuracy of plastic sorting, allowing for better separation of plastic types and reduction of contamination.

- Chemical Recycling: This emerging technology, which breaks down plastics to their chemical components, offers a solution for recycling plastics that are currently non-recyclable through mechanical processes. It has the potential to revolutionize the plastic recycling industry by turning waste into valuable raw materials.

- Biodegradable Plastics: The development and use of biodegradable plastics could reduce the dependence on traditional plastics and improve the manageability of plastic waste, aligning with circular economy principles.

- Global Expansion of Recycling Facilities: As more countries adopt stricter waste management and recycling policies, the demand for advanced recycling facilities is likely to increase, promoting a more global approach to plastic recycling.

Challenges

- Technological Limitations: Despite advances, recycling technologies still face limitations, particularly in handling mixed or heavily contaminated plastics, which can hinder the quality and viability of recycled products.

- Regulatory Policies: Inconsistent and evolving regulatory frameworks across different regions can complicate the operations of recycling companies, requiring them to adapt continually to new standards and practices.

- Market Acceptance: The demand for recycled plastics can be unstable, influenced by economic factors and competition from cheaper virgin materials. Creating stable markets for recycled products is crucial for the sustainability of the recycling industry.

- Financial Constraints: High initial investments for state-of-the-art recycling facilities and ongoing operational costs can be prohibitive, especially for startups and smaller companies.

Conclusion

Plastic recycling machines are indispensable tools in our fight against plastic pollution. By converting waste into valuable materials, these machines not only mitigate the environmental impacts associated with plastic disposal but also contribute to the conservation of resources and reduction of greenhouse gas emissions. Their role in fostering a circular economy is vital, as they enable the reuse of materials and reduce our reliance on virgin resources.

To continue advancing in this field, broader social participation and technological innovation are essential. Consumers, businesses, and governments must collaborate to enhance recycling practices and develop new technologies that overcome current limitations. Support for research and investment in more efficient and versatile recycling solutions will drive the industry forward, making the recycling of all types of plastics more feasible and economically viable.

By embracing these challenges and opportunities, we can ensure that plastic recycling machines continue to play a critical role in sustainable environmental development, helping to create a cleaner, greener, and more sustainable future for all.